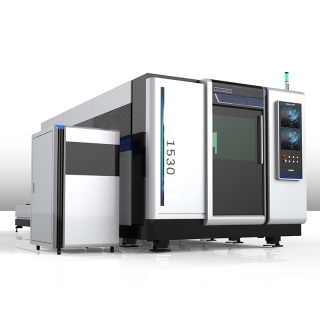

Single Bed Fiber Laser Cutting Machine

Fiber laser cutting machine applications

Fiber laser cutting machine is widely used in advertising, high pressure / low voltage electrical cabinet production, textile machinery accessories, kitchen appliances, cars, machinery, elevators, electrical accessories, spring coil pieces, metro line parts and other industries.

Fiber laser cutting machine

Features

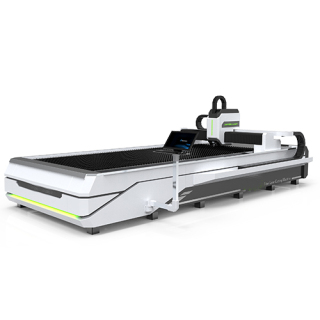

1.Machine Body--Welding Machine Body .High strength, not easily deformed.The following features ensure that the bed will not be deformed for 20 years like high strength, good stability and strong tensile strength.More stable.The rectangular tube has a wall thickness of 6 mm and the entire body weighs 3,000 kg.

2.Laser Head--Swiss Laser Head--Raytools Brand.Collimating Lens and Focal Lens Adopt Compound Lens,to Obtain the Obtimal Optical Quality and the Cutting Effect. Completely Sealed Internal Structure of Laser Head can Avoid Optical Part Polluted by Dust.

3.Aviation Aluminium Cross-Beam

a.High toughness and ductility

The aerospace industry extrudes aluminum profiles and undergoes fine processing after extrusion molding and quenching heat aging to make the overall rigidity and surface quality of the beam very good.

b.High speed and precise cutting

The beam structure optimized by finite element analysis, based on the metal characteristics of aluminum alloy, is corrosion-resistant, lightweight, high rigidity, which guarantees the high-speed movement during laser processing, and high-speed cutting of various patterns can be achieved under the condition of satisfying accuracy.

c.More efficient

The aluminum profile beam of the aerospace industry allows the equipment to have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

4.Water Cooling System–Hanli Brand. Dual Cooling Function:Laser Source Cooling, Laser Head Cooling.Multiple Protection Functions,Passive Alarm Terminals and Remote Control Terminals.

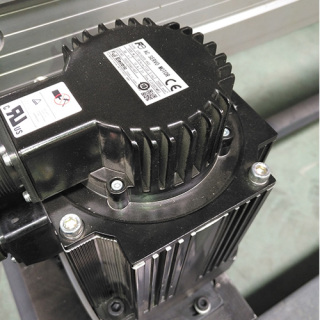

5.Fiber laser cutting machine adopts international famous brands, such as Taiwan HIWIN guide rail & YYC rack, Japanese YASKAWA servo motor motor & SHIMPO reducer, which guarantees high running speed, acceleration, accuracy and stability.

Applications:

G-CUT fiber laser metal cutting machine is widely used in various industries, such as aerospace and automotive industry, advertising industry, decoration industry, kitchen and kitchen ware, engineering machinery, steel and iron, automobile, metal plate chassis, air-conditioner manufacturing, metal plate cutting, metal craft, building model, etc.

Parameters:

Model | 1325 1530 2040 2060 |

Working area(mm) | 1300X2500mm 1500X3000mm 2000X4000mm 2000X6000mm |

Fiber laser power(W) | 1000-12000W |

Laser wavelength | 1070nm±10nm |

Max moving speed | 120m/min |

Max cutting speed | 30m/min |

Max acc. speed | 1.5G |

Transmission | Double drive design, high precision rack gear and rail |

Driving system | Servo motor |

X Y positioning accuracy | ±0.02mm |

X/Y repeat positioning accuracy | ±0.02mm |

Working voltage | 380V/50HZ |

Plate positioning | Automatic edge search positioning |