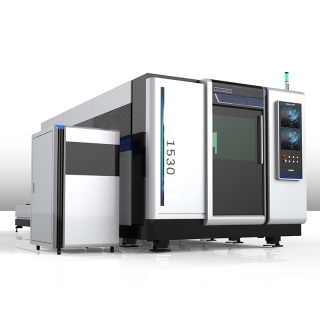

Fiber Laser Cutting Machine with MAX laser souce

G-CUT fiber laser metal cutting machine is widely used in various industries, such as aerospace and automotive industry, advertising industry, decoration industry, kitchen and kitchen ware, engineering machinery, steel and iron, automobile, metal plate chassis, air-conditioner manufacturing, metal plate cutting, metal craft, building model, etc.

We can produce 500 sets of fiber laser cutting machine every month.

The metal cutting machine sales of Chinese market and abroad market can be one hundres billion.

Features

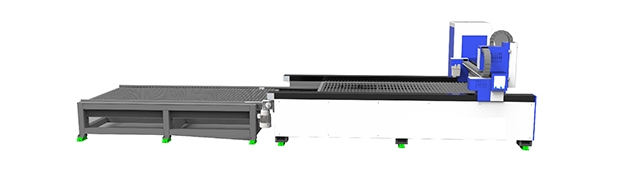

1.Exchanging Platform.It adopts an up and down exchange platform;The converter is responsible for controlling,the exchanging motor;The machine is able to finish the platformexchanging within 15s.

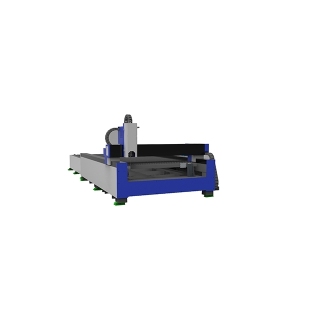

2.3rd Generation Aviation Aluminum Gantry.It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

3. The Segmented Rectangular Tube Welded Bed.The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.High strength, stability, tensile strength, ensuring 20 years of use without distortion;Thickness of rectangular pipe wall is 10mm,and weights 4500 kg.

4. Fiber laser cutting machine laser head is without manual operation, it can focus automatically.

a.Without manual focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

b.Bigger adjustment range.Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

c.Long service life.Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head.

5.Transmission and Precision.G-CUT fiber laser cutting machine is equipped with Taiwan YYC rack, Japanese Yaskawa motor and French Motoreducer. The repeat positioning accuracy of the machine tool can be 0.02mm and the cutting acceleration is 1.5G. The working life is up to 10 years.

Parameters

Model | 1530E 2040E 2060E |

Working area | 1500X3000mm 2000X4000mm 2000X6000mm |

Fiber laser generator | Raycus MAX IPG |

Fiber laser power | 1000W 1500W 3300W 4000W 6000W 12000W |

Transmission | Rail and rack gear |

Max moving speed | 120M/MIN |

Max accelerated speed | 1.5G |

X/Y position accuracy | ±0.03mm |

X/Y repeat position accuracy | ±0.02mm |

Working voltage | 380V/50HZ |

Max loading of the worktable | 1600KG |

Gross weight of the machine | 15T |